Word from a client: Aseco

Comments Off on Word from a client: Aseco

The sustainable disassemblement of cargo ships

A look inside the process

Freighters have a long durability. They can be used for decades before needing replacement. But even for these huge vessels there comes a time when they’re put out of commission. Getting rid of tons of steel is however no easy job. They’re often dumped and get washed ashore. Frank Geerdink, Director of Aseco Europe B.V, found a sustainable solution for this problem.

To make this project possible, Aseco has collaborated with CMT. In the CMT shipyard decommissioned ships are cut up in different parts by using huge cutting wires. At the end of this extensive process, all that is left are big slices of metal. Some of these parts can be molten into steel, others get turned into recycled products. Aseco even manages to produce energy from some leftovers!

They main advantages of disassembling ships in such a manner:

- It’s a 100% save; for the surrounding environment, nature and people.

- It reduces Co2 and also reduces air and water pollution.

- A safe environment can be created without having to disassemble a ship directly in the ocean (which often leads to pollution).

- It’s an automated system that doesn’t require hard and physical labour from workers.

Are you curious about this disassemblement process? Check the video below.

The challenge

enthusiasm by the team. Sustainability is an important pillar for Alcomex. So having the opportunity to collaborate with Aseco on such an important project fits perfectly with Alcomex.

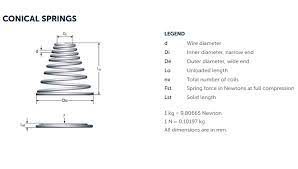

Aseco required very specific pressure springs to place in between large steel pearls. The mechanical process could not function without these springs. They also needed to be dirt resistant in order to make the disassembling process economically viable. And to be able to cut straight through freighters the springs had to be especially strong. Such a complex project requires a custom solution; a service that Alcomex offers.

Before the project could be launched, Aseco and CMT international required approval and subsidies. Due to the complexity of the project it took several years before all requirements were met. Luckily in 2022, approval was given and they could finally start.

The solution

Before Alcomex could start their production process, a couple of NDA’s needed to be signed. Because the project was still in its first stage, confidentiality had to be assured. After signing however, Alcomex started manufacturing the specific springs required by Aseco. By installing the springs within a certain distance of one another, it was possible to cut through the ships.

Frank Geerdink, Director of Aseco about Alcomex.

The deciding factor to work with Alcomex was their way of communication. They understood in rapid time what we needed in order to run our first tests. The fact that they were able to custom make the products that we needed, exactly at the right time, is even further proof that we choose the right company to work with.

Are the Alcomex Springs important? Without a doubt! Even though 5 other businesses sent their springs for testing, the clear and concrete manner of communicating by Alcomex was by far superior.